A clay brick making production line is an industrial system that transforms raw clay and shale into durable building materials through a series of automated processes. These lines are essential for the construction industry due to the consistent demand for bricks in various civil engineering projects.

For the technology for brick setting, there are 1 time setting or direct setting or 2 times setting by robots.

After the raw clays are digged out, they will be aging in the aging room for 1-3 months before production.

Excavator in the aging room Raw Material Preparation of Equipment from BBT:

Raw Material Preparation of Equipment from BBT:

Workshop for clay brick making machine

This part involves mining the surface clays, shales, or mudstones, which are then transported to the plant. Here, they are cleaned of impurities like stones and organic matter, crushed into powder using roller machines, and mixed with water and potentially additives (such as fly ash or pigments) to achieve the right plasticity and consistency. This is often done in a wet pan mill to remove air pockets and ensure uniformity.

Equipment of the clay brick making machine for general arrangement for the raw materials preparation as following: Box feeder--tooth roller crusher--primary roller crusher--double shaft extruding mixer--refine roller crusher/roller mill--wet pan mill--front grid extruder--vacuum extruder .

Box Feeder in auto clay brick making line  Tooth roller crusher in working site

Tooth roller crusher in working site Refine roller crusher/roller mill for output diameter 1 mm

Refine roller crusher/roller mill for output diameter 1 mm Wet pan mill in working site

Wet pan mill in working site extruding mixer in working site

extruding mixer in working site Front grid extruder in working

Front grid extruder in working Forming/Molding: The prepared clay is shaped into "green" (unfired) bricks. Common methods include: Extrusion: A continuous column of clay is forced through a die and then cut into individual bricks by the column cutting systems and then green brick cutting systems will cut the columns into bricks.This is typical for high-volume production and for making perforated bricks.

Forming/Molding: The prepared clay is shaped into "green" (unfired) bricks. Common methods include: Extrusion: A continuous column of clay is forced through a die and then cut into individual bricks by the column cutting systems and then green brick cutting systems will cut the columns into bricks.This is typical for high-volume production and for making perforated bricks.

Clay brick cutting systems for column cutting and green brick cutting

Clay brick cutting systems for column cutting and green brick cutting Programming, automatic loading and unloading sytems---Automatic loading and unloading systems for clay hollow blcoks 400x200x200mm

Programming, automatic loading and unloading sytems---Automatic loading and unloading systems for clay hollow blcoks 400x200x200mm Automatic loading and unloading systems of 3D drawings for clay brick

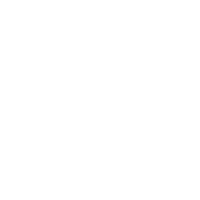

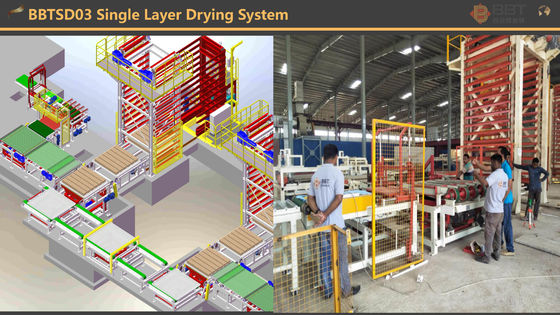

Automatic loading and unloading systems of 3D drawings for clay brick Brick Drying: Green bricks can be dried in chamber dryer or tunnel dryer. The green bricks contain excess moisture and must be dried slowly and evenly to prevent cracking or warping. This is typically done in large dryer, often using waste heat recovered from the firing process of tunnel kiln for efficiency saving.

Brick Drying: Green bricks can be dried in chamber dryer or tunnel dryer. The green bricks contain excess moisture and must be dried slowly and evenly to prevent cracking or warping. This is typically done in large dryer, often using waste heat recovered from the firing process of tunnel kiln for efficiency saving.

Tunnel Kiln for clay brick firing (Burning): The dried bricks are fired in a tunnel kiln at 860-950 degree to achieve their final hardness, strength, and desired color. Modern facilities largely use highly efficient tunnel kilns, where bricks on kiln cars move through different temperature zones.

Tunnel Kiln for clay brick firing (Burning): The dried bricks are fired in a tunnel kiln at 860-950 degree to achieve their final hardness, strength, and desired color. Modern facilities largely use highly efficient tunnel kilns, where bricks on kiln cars move through different temperature zones.

General arrangement for tunnel kiln and dryer in the production line of clay brick making

General arrangement for tunnel kiln and dryer in the production line of clay brick making Kiln cart running equipment

Kiln cart running equipment Automac pckaging systems for fired bricks

Automac pckaging systems for fired bricks Kiln cart cleaning machine in the production line of clay brick making

Kiln cart cleaning machine in the production line of clay brick making

BBT supply full auto clay brick making line machinery and equipment

TCNL series of Chain full steel type box feeder

TWGD series of double shaft mixer

GS series of roller crusher

TRA series of double tooth roller crusher

TWJH series of front grid extruding mixer

TWPM series of wet pan mill

QTQG series of cutter

EV series of vacuum extruder

Robot setting machine

Brick machine spare parts

BBT provide full automatic clay brick making project design, construction and technical supporting.

XI'AN BBT CLAY TECHNOLOGIES CO.,LTD

Noda Pan

nodapan@claybbt.com

WA/wechat+86 177 9142 2086

www. claybbt.com

www.claybricksmakingmachines.com

www.claybbt.ru

YouTube: https://www.youtube.com/@BBTChina

Facebook: https://www.facebook.com/bbt15/

Linkedin:https://www.linkedin.com/in/noda-pan-56a524236/